Cone Crusher Touch

2019-12-23T09:12:42+00:00

Cone Crusher Fodamon Machinery

Principle of Cone Crusher Cone crusher crushes materials by the working surface between the movable cone and fixed cone The movable cone of the cone crusher is supported by spherical bearing and fixed on an hanging erect shaft which is set in the Cone crusher is a machine suitable for crushing stone materials in the industries such as metallurgy, building, road construction, chemical engineering and nitrate, and widely applied in various departments of mining, highway, railway, water conservancy, chemistry, etc PLC+ touch Cone Cursher In Highquality Fote Machinery(FTM)MEKA’s cone crusher is a very good example of our determination to gain customer trust in the field of crushing and screening equipment The solid structure required for crushing very hard materials allows the operators to employ the cone crusher for a wide range Cone Crushers MEKA Crushing Screening Plants

Sandvik Cone Crushers — SRP

Sandvik cone crushers are an excellent choice in secondary, tertiary, quaternary and pebblecrushing applications They are equipped with the hydraulic Hydroset™ system, which provides safety and settingadjustment functions Our crusher automation system delivers realtime performance management, enabling you to monitor and optimize crusher All of our Trio® TP cone crushers feature a steep crushing chamber angle, a large crushing stroke, high pivot point, and optimum speed to deliver a finer product through increased interparticle comminution Being Synertrex® enabled means you can monitor the operation and health of Trio® TP Series Cone Crushers Weir Group Continuous crusher feed through CFS (Continuous Feed System) Cone crusher with large stroke Efficient and powerful diesel directdrive Simple control with menuguided touch panel Wide and robust crusher discharge conveyor Simple transport Powerful secondary screening unit (MCO 9 S) Good linkage option High output and availabilityMOBILE CONE CRUSHERS MOBICONE EVO Wirtgen Group

Mobile Cone Crusher Range PowerX Equipment

The high performance ® 1150 Maxtrak is a medium sized cone crusher which has been designed for direct feed applications without prescreening on clean rock At its heart is the Automax® cone crusher which provides excellent reduction and product cubicity for the production of high quality aggregate and subbase material Usually, a cone crusher is installed in a crushing circuit as a secondary crusher Precrushed material fed in via the top of the cone crusher flows over the mantle while the vertical cone crusher MCC Series Cone Crusher Minyu Machinery pressive crushing has been proven to be one of the most energy efficient principles for breaking rock particles (Schönert, 1979) In this paper the cone crusher, which utilizes this mechanism, is investigated using the discrete element method (DEM) and industrial scale experiments The purpose of the work is to develop a virtual simulation environment that []Cone crusher modelling and simulation using DEM

Sandvik Cone Crushers — SRP

Sandvik cone crushers are an excellent choice in secondary, tertiary, quaternary and pebblecrushing applications They are equipped with the hydraulic Hydroset™ system, which provides safety and settingadjustment functions Our crusher automation system delivers realtime performance management, enabling you to monitor and optimize crusher performance and productivityThis crusher can be operated remotely using a PC and be fully integrated into the plant's control system if required In addition, our Trio® TP series cone crushers feature a selfcontained, climatecontrolled oil lubrication skid with integrated programmable logic controller (PLC) monitoring condition sensors Trio® TP Series Cone Crushers Weir GroupCone Crusher Introduction: Cone Crushers is widely used in mines, cement plants and sandstone industries for medium crushing of various mine rocks, such as iron ore, copper ore, nonferrous metal ore, granite, sandstone, etc Working principle is as follows: The cone body swings under the force of the eccentric shaft sleeve, so that the concave is sometimes close to and sometimes away from Cone Crusher Rhyther Mining

Cone Crusher Good Crusher with Reasonable Price

Various Types of Cone Crusher from Excellent Company As we know, the cone crushing machine is the main equipment which is used for metallurgy, chemical industry, building materials, road construction and other industrial sectors to crush and finely crush various ores or rocks or other different harnessThis GC300 Cone Crusher is guaranteed to deliver high performance and dependability, and is manufactured from high endurance quality materials at our UK headquarters STANDARD FEATURES • Instantaneous CSS adjustment • Fully integrated crusher control system complete with a 14" touch screen to give full process control • Easy site assemblyGiant Crushing: The GC300 Cone Crusher Giant Optimum crusher settings are maintained via remote adjustment, with the crusher operator able to initiate an automated calibration process via a touchscreen monitor The operator can also modify the crusher setting at any time, even while crushing, with the system providing warnings when liner wear reaches various set levels between 50% and 100%Cone Crushers: The Suppliers’ Perspective E MJ

coal cone crusher specifications ataFinch

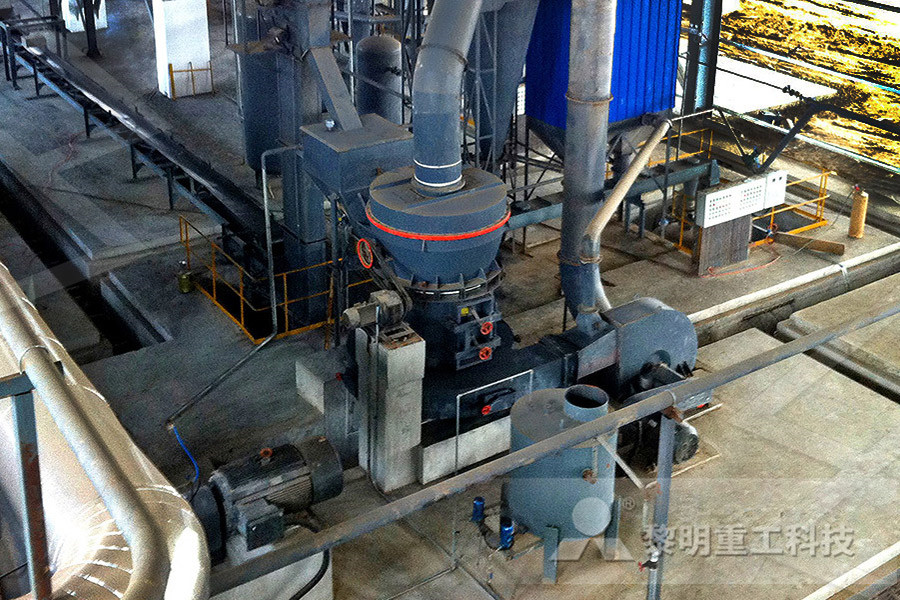

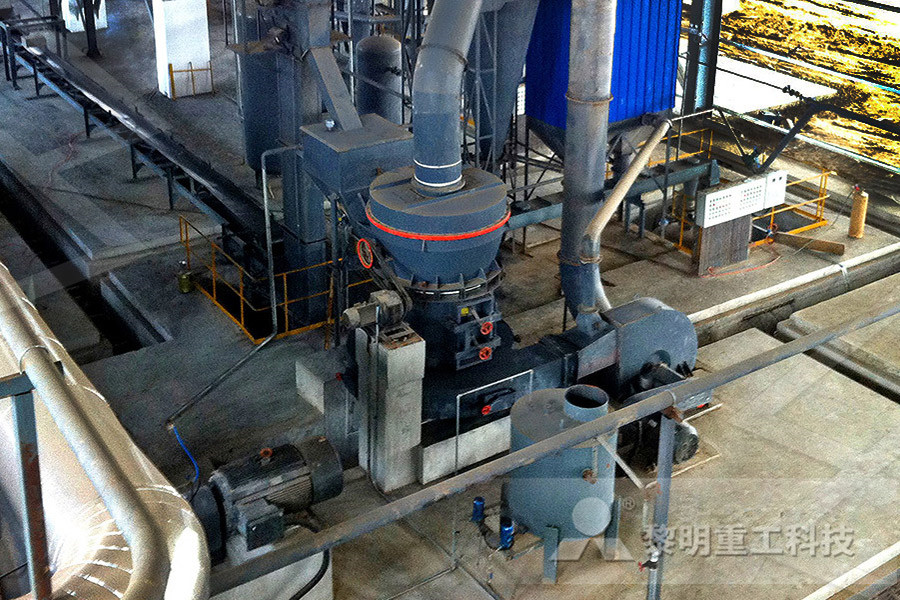

coal cone crusher specifications tsuriai heavy coal cone crusher specifications jawcrusher350tph afvalcontainerscatcobe jawcrusher350tph Industrial uses the jawcrusherimpactcrusher cone crusherand sand making machine as the core crushing equipment On this basis we have developed 10 series and more than 100 models to form high medium and low The Raptor 350 offers a mobile closed circuit plant Productive and versatile, the 350 Cone Crusher is readily mounted and easily transportable on a portable cone/ screen chassis The 350 is a smart cone crusher with advanced control systems Raptor 450 The Raptor 450 cone crusher is ideal as a secondary crusher following a JawRaptor® Cone Crusher best in class Create a Globally Renowned Mining Machine Brand Leimeng Machinery specializes in RD and manufacturing of large crushing and screening equipment (cone crusher, impact crusher, impact crusher, jaw crusher, sand washer, vibrating screen, feeder, belt conveyor) ) and professional mining equipment and modern hightech enterprises that provide relevant technical adviceChina large crushing and screening equipment, cone

Application of DEM to simulate a cone crusher

The DEM model will be used to optimize the performance of the cone crusher Assuming the calibration step is performed, the DEM model can be used to predict the cone crusher performance for other ores without need of any experimentation which ultimately leads to save capital cost and time Equiptrade Symons Cone Crushers For Sale 26th March 2019 8th July 2020 Admin Plant , Promax Crusher Range , Quarry Plant As appointed dealers we are pleased to offer new Equiptrade Symons Cone Crushers for sale Sizes available : 2ft, 3ft, 4 1/4ft, 5 1/2ft and 7ft HDCone Crusher Archives Promax International The fully automatic control system of PCL with a touch screen ensures the safe operation of the equipment 3 Long service life The singlecylinder hydraulic cone crusher of adopts the concept of the constant cavity, highquality materials, and reasonable design and manufacture, which makes the life of the lining board the longest, thus Singlecylinder Hydraulic Cone Crusher Is An

Cone Crusher Radius

HType cone crushers are suitable for a wide range of applications, including quarrying mining End products are final aggregates for concrete and road projects, Cone crusher series combine extremely high performance with low total cost Optimum crusher settings are maintained via remote adjustment, with the crusher operator able to initiate an automated calibration process via a touchscreen monitor The operator can also modify the crusher setting at any time, even while crushing, with the system providing warnings when liner wear reaches various set levels between 50% and 100%Cone Crushers: The Suppliers’ Perspective E MJcoal cone crusher specifications tsuriai heavy coal cone crusher specifications jawcrusher350tph afvalcontainerscatcobe jawcrusher350tph Industrial uses the jawcrusherimpactcrusher cone crusherand sand making machine as the core crushing equipment On this basis we have developed 10 series and more than 100 models to form high medium and low coal cone crusher specifications ataFinch

MOBILE CONE CRUSHERS MOBICONE EVO Wirtgen Group

Continuous crusher feed through CFS (Continuous Feed System) Cone crusher with large stroke Efficient and powerful diesel directdrive Simple control with menuguided touch panel Wide and robust crusher discharge conveyor Simple transport Powerful secondary screening unit (MCO 9 S) Good linkage option High output and availabilityModular Cone Crusher Range (Range: 36D 38SBS 44SBS 52SBS 57SBS) The general specifications for this modular plant are: Osborn Cone Crusher (Selected by duty) Universal crusher base mounted on rubber isolation clamping pads to minimise cyclic exciting forces to the rest of the structure Skid type structure c/w walkways, handrails, access ladders, motorModular Cone Crushers Home Welcome to OPS Improve your crusher’s productivity by up to 20% with our new generation upgrades Now your Symons crusher can incorporate the safety and performance features of Outotec’s modern crushers: Hydraulic Lock Posts for bowl clamping at the touch of a button; Hydraulic Motor Bowl Adjustment adds a gear ring for easier and faster adjustmentSymons Cone Crusher Parts Upgrades Outotec

MOBICONE MCO 9/9i EVO Wirtgen Group

Crusher Cone crusher type KX 200 Crusher system size d= (mm) 970 Crusher weight approx (kg) 8,900 Crusher drive type, approx (kW) direct, 160 Plant performance at 032 mm approx (t/h) 220 Plant performance at 063 mm approx (t/h) 270 Crusher discharge conveyor Width x length (extended) (mm) 800 x 8,800 (10,400) SINCO Machinery manufacture an extensive range of aftermarket crusher wear and spare parts to suit the ™ ™ range of HP700 cone crushers SINCO Machinery have developed an extensive range of manganese to suit the crushing chambers available for each model HP700 Cone Crusher Parts Sinco

mobile jaw crushers inspection checklist

liner separator in flotation beneficiation plant

quartz machines grains

Mining Land Reclamation

ball mill mining equipment

stone crusher machine ne kenya

gypsum grinding plant manufacturers

used granite crushing equipments for sale in usa

Equipment For Processing Of Thin Gold

ball mill for veolia process

cara menghitung produksi batu pecah menggunakan crushing

Uj440I Cone Crusher Dimensions

crushing and grinding circuit flow diagrams

Who Own The Gold Mine In South Africa

illegal crushing site in bridgeport ct boucher

Solution For Mobile Stone Crushing Equipment

ball mills for cement making

crusher sand washing plant australia

wheel mounted mobile crusher for sale nignia

Gold Quarrying Plant Sale Sudan Quarrying Crusher

hot stable quality stone hammer crusher plant

Stone Vertical Combination Crusher Of Impact Crusher

devaney limestone quarry russellville al

cereal grinding domestic

mine for sale north carolina

imagenes de molinos para moler la yerba

Antique jaw crusher italy

Manufacturers Of Cone Type Stone Crushers

clinker crushing equipment projecthard

Designers Of Mobile Jaw Crusher Stone Crusher Machine